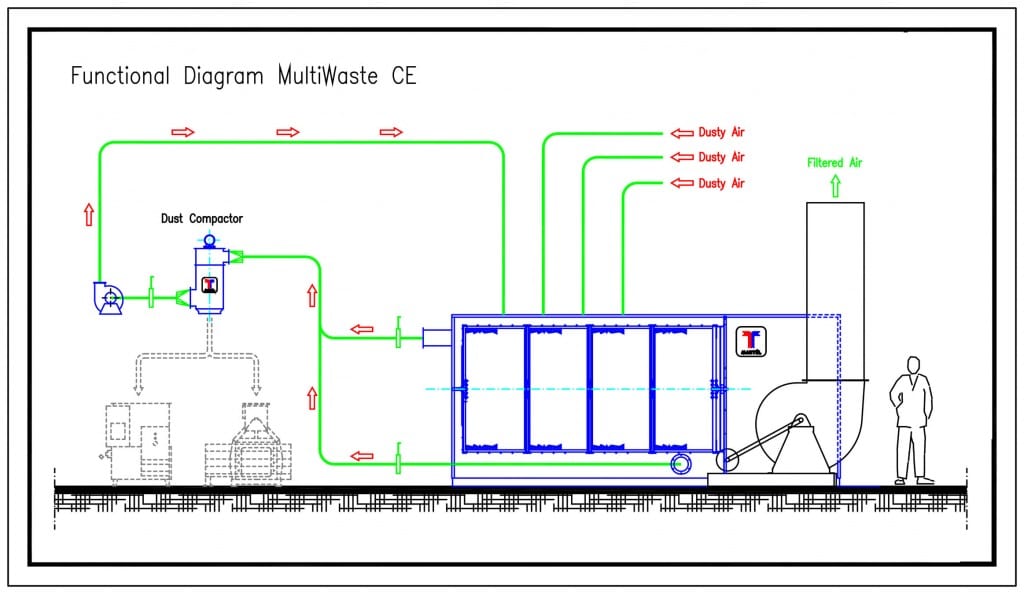

The Multi Waste filter is a completely different system that solves the explosion risk at its root, without using any water in the process. Multi Waste achieves this result because it’s a dry filter with a continuous cleaning system that removes the dust preventing the accumulation inside the filter. In fact, the dust is continuously and automatically compacted by a worm screw and expelled to be disposed, or recycled when possible.

Dusty air enters into the top side of the main chamber of the Multi Waste filter and then is uniformly distributed on the self-cleaning cylinder. During this process the air is forced to rotate around the cylinder releasing eventual heavy particles in a specific collection point. Finally the air passes through the cylinder leaving the fine dust on the filtering surface where cleaning nozzles continuously removes the dust. The dust is then sent to the compactor.

The biggest benefits of the Multi Waste system are:

• Absence of explosion risk.

• Reduction of energy consumption (for example a bag filter for 100’000 m3/h needs roughly 36 Kw of energy plus the energy for the compressed air; a Multi Waste for 100’000 m3/h needs only 18 Kw without any additional source of energy).

• Reduction of spaces necessary for the filtering plant.

• Fast installation thanks to preassembled transportable version.

• Possibility of installation inside or outside of the building.

• The air capacity of the Multi Waste system depends on the model and on the filtering class requested by the customer; but in any case the range is:

- From 10’000 m3/h to 80’000 m3/h for the preassembled version, transportable on standard truck.

- Till 180’0000 m3/h for the “Multi Waste Export” version, that is prefabricated but not assembled and it can be shipped in standard containers.