Functioning and purpose

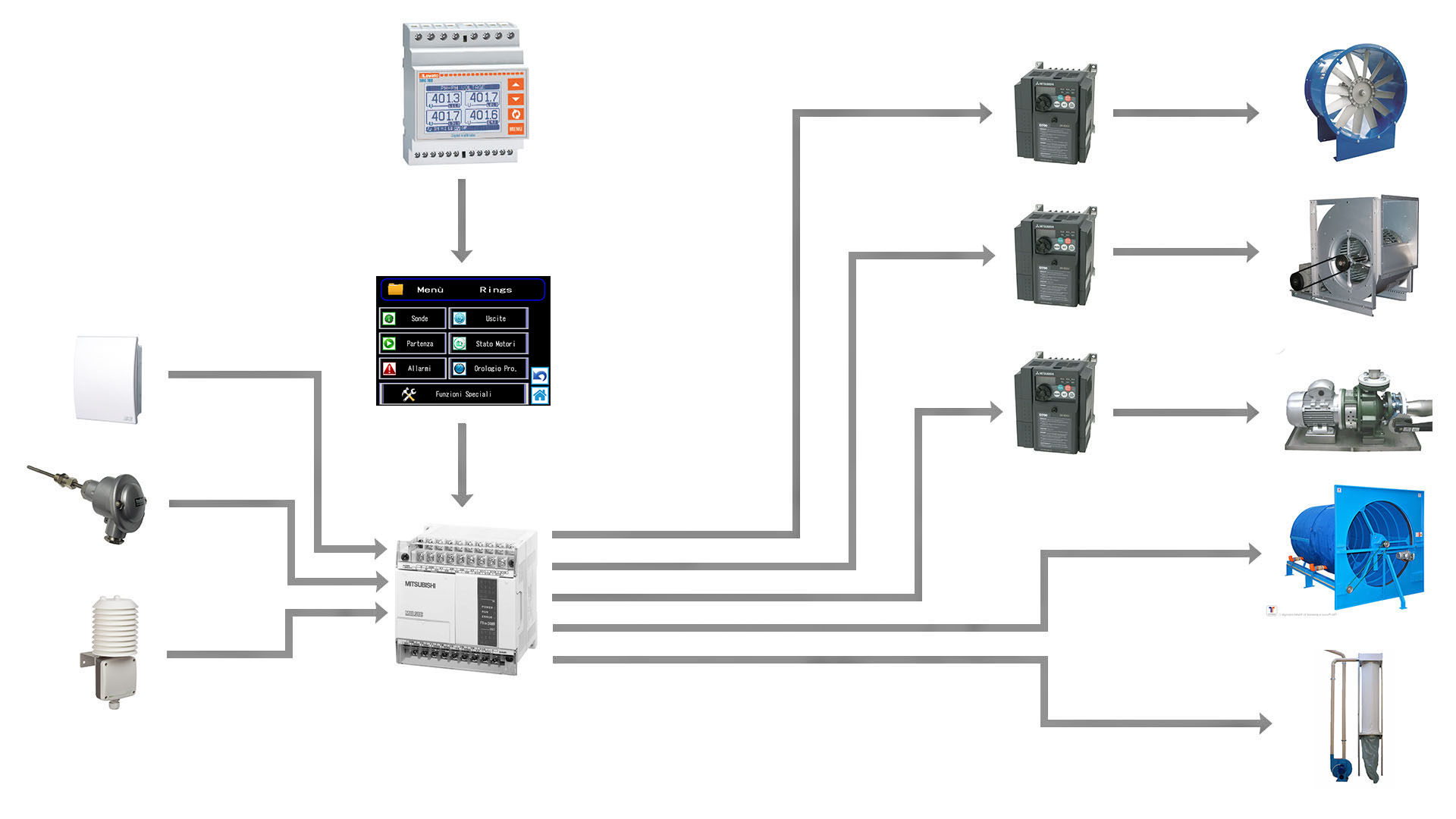

The software at the base of the Eco Energy® constantly compares the values obtained (probes) with respect to the desired values (set-point) and regulates the motors in such a way that the desired values are achieved and kept stable. At the same time, it contains the speed of the engines, varying continuously according to changes in the needs of the department and the external climatic conditions.

The energy saving achievable with Eco Energy® is on average 30% of the annual consumption (typical system with continuous use and except for lack of maintenance or improper use of the plant) and includes the following components:

• Inverter for fans and pumps complete with anti-noise filters.

• Additional relays for the electrical panel for switching off components that do not require continuous use, such as self-cleaning filters, baggers and compactors.

• Programming of the PLC that manages the system to optimize the use of the various motors so as to reduce consumption to the minimum necessary.

• Electrical consumption analyzer mounted inside the electrical panel of the plant.

It is an independent device that can not be modified by Martèl and this ensures the customer an effective reading of consumption.

The consumption detected is transmitted to the Martèl PLC which makes them visible on the instrument display and transmits them to the i-Monitor® system.